If you understand operations management, you can see how good MPS is

And if you know Mark Crompton, Operations Director at Meggitt Avionics, then you’ll know that this is praise indeed. “It’s the broad engagement it achieves that makes me confident we really will succeed in inverting the pyramid [that is, putting the rest of the organisation, including senior management, at the service of the makers]. In the past I’ve seen it tilt and I’ve seen it wobble. But this time it’s going to go.”

That’s not to say Crompton didn’t have his doubts initially. But they didn’t last past the first training. “At boot camp [the intensive Meggitt Production System (MPS) training for site leaders] I could see that this had been designed to build on the existing Lean and continuous improvement knowledge of people like me. But things like the Leader Standard Work and the ‘no fly zone’ idea [which keep the early morning clear of meetings so everyone can attend their Daily Layered Accountability meetings], these are clever ideas and they really work. Amir [Allahverdi], Louis [Chavez], Mike [Haney] and the rest of the MPS team have done a really good job with this. They clearly know exactly what they are doing. MPS is as well-structured a system as I have ever seen.”

Companies often like to say they do Lean when in reality they do kaizen events or fixes

Taught by the Japanese

And Crompton has seen a few. He spent eleven years at Aerostructures Hamble (now part of GE Aviation), first as operations director and then for eight years as managing director. When they won a large Boeing contract he and the company had the benefit of working with the Japanese Shingijutsu consultancy founded by three of the original Toyota Production System pioneers.

“Companies often like to say they do Lean when in reality they do kaizen events or fixes. That was us really. Boeing used to send lots of people round our plant. We were probably their supplier with the best Lean operation in Europe. But in comparison to MPS, we were nowhere near getting the ‘visual’ factory up and running and nowhere near getting broad-based engagement in daily operations using something like Daily Layered Accountability.”

Off the top of his head, Crompton cannot think of a single person at Meggitt Avionics (MAV) who is not involved in an MPS-related continuous improvement process.

Started on the shopfloor

His early days on the shopfloor and then as a young engineer, living the decline of British manufacturing in the 1980s, have made Crompton almost evangelical about what he calls “full engagement”.

“When I started out we had a form of Lean. It was called ‘method time and motion’ (MTM). Every little detail of a process was standardised, with time stripped out second by second and the ergonomics measured and perfected. The hosiery plants I visited as a young production engineer were the leanest you could imagine. Those women worked unbelievably hard and never stopped.”

MPS reminds us that the people who really know how to do a job are the people who do that job. They are first to see a problem and the opportunities to improve

Continuous improvement was embedded in the system of ‘piece rate’. Because operators were paid a negotiated rate per unit, they could take all the benefit of any efficiency gains made before the next round of rate negotiations. This created a constant incentive to develop short-cuts and make special tools, improving the process and shortening production time. And, since operators had to carry the cost of errors, quality was maintained as well. “I worked under that system, building axles,” recalls Crompton. “It generated a very high degree of what we now call engagement, I can tell you.”

The system broke down under the twin pressures of union power and fierce cost cutting. Out went time and motion but nothing replaced it. This was the era of ‘I don’t pay you to think!’ and ‘us and them’. “Very many British factories were culturally bereft back then,” Crompton recalls with sadness. “People still wanted to be engaged and wanted to do a good job. But for a long time no-one ever asked.”

Lean on me

All of which explains why the strength of MPS buy-in across MAV hasn’t really surprised him. “Of course people want to be involved in improving their own work. Why wouldn’t they? MPS reminds us that the people who really know how to do a job are the people who do that job. They are first to see a problem and the opportunities to improve. They often know best what will and won’t work. There’s a lot of people involved in this business who have been here for a very long time. We’ve got a guy who’s been working on oxygen products for 40 years. [Take a bow Laurence Hawkins.] The right question for management to be asking has always been, how can we bring all that knowledge back to the table? Now, with DLA, we have a system that can do just that.”

DLA underplayed

It would seem, then, that DLA has no bigger fan than Mark Crompton. “I’ve heard it said that DLA is being overplayed in MPS roll-out. I disagree. If anything, it’s being underplayed. It is so powerful. Get DLA working right and the other parts of MPS almost fall into place. The Living Pareto charts alone are incredibly powerful, giving you very nearly the whole story.”

DLA unleashes a complex mix of factors which can completely transform working culture in a very short time, he says. “For example, DLA has made our failures very visible. So, because we all look at them every day at morning DLA meetings, we are ‘living’ them, not trying to sweep them under the carpet. At the same time we are all involved in developing and applying solutions, ‘countermeasures’, and allocating individual responsibilities for chasing them up and seeing them through.”

The effect this has had on attitudes is at least as striking as the impact on the KPIs themselves. “Before DLA deployment, on-time delivery [OTD] was as low as 80% and that was viewed as the norm. Perhaps the mountain felt too big to climb. From 20 ‘lates’ a week we are now down to just one. But more people feel more distraught about that one, than they ever did about the 20.”

I’ve heard it said that DLA is being overplayed in MPS roll-out. I disagree. If anything, it’s being underplayed. It is so powerful

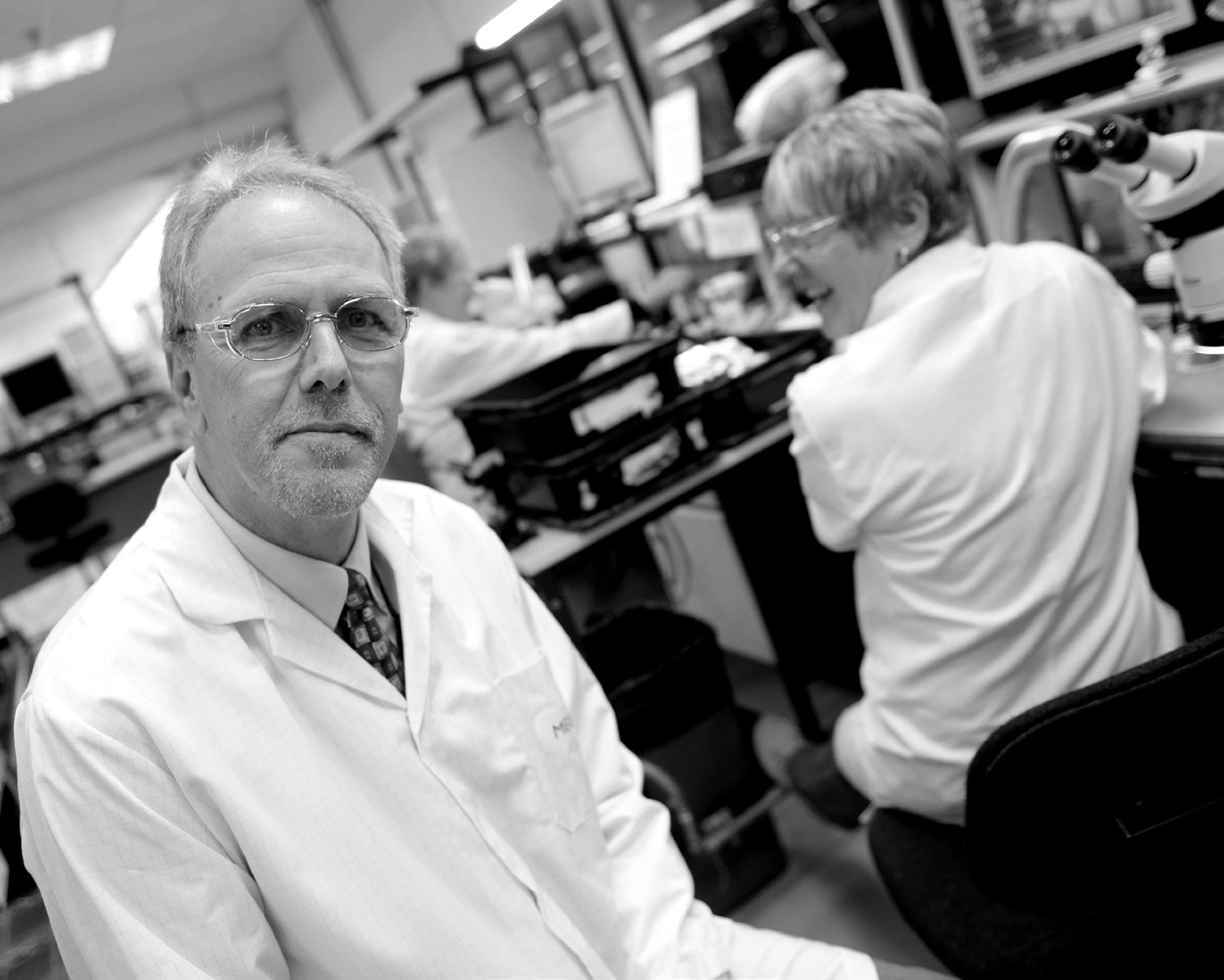

Above: Mark Crompton: Customers want suppliers who make life easy for them and when they find them, they stick with them. With MPS, I believe Meggitt can become one of those no-issues suppliers.

DLA unleashes a complex mix of factors which can completely transform working culture in a very short time

Walking the walk

Nor should we underestimate the importance of MPS in changing how MAV is managed and led, says Crompton. “If you don’t lead by example, how are you going to convince people that the MPS vision of inverting the pyramid isn’t just hot air? When I arrived here I met staff who said they had been through a time when directors were not seen much. Things are very different now. With the introduction of DLA the senior team is far more visible to the wider workforce. We all make a point of attending the DLA meetings and Annette [MAV’s MD] is at every Focus Factory and as many DLAs as she can manage. So people have started to understand that we are serious about this and that they are being listened to.”

What customers want

Crompton is not the sort of man to get over-excited about what’s been achieved so far. He’s too much of a realist for that. “We’ve made a good start—OTD, DPPM [defect parts per million], these are good—but we’ve really only broken the ice. There’s so much more work to do. We’ve just settled into the new factory and we are really only just getting started with defining where the quality and productivity improvement focus needs to be.”

But even he can’t suppress a smile when he talks about what’s possible. “So far we’ve been focusing on operations. But Annette has already got everyone, right across the functions, looking at how MPS ideas and techniques can be applied to everything MAV does. So we are just starting to understand the real power of MPS and it is very impressive.

“Fundamentally this is about growing the company—by pleasing customers—by giving everyone in the company what they need to succeed in their work. It’s not easy getting the big aerospace companies to pay premium prices. But in my experience, if you are easy to work with, deliver on time and the bits all fit, then you can. What people like Boeing want is suppliers who make life easy for them. When they find them, they stick with them. With MPS, I believe Meggitt can become one of those ‘no issues’ suppliers.” ■

MARK CROMPTON’S TOP TIP

Don’t forget the 7th ‘S’

Crompton likes to talk about “the 7th S”. It stands for ‘shovelling’ (allegedly) but he has a serious point. He means clearing the decks, creating order, making space. More than 100 tons of redundant kit and materials had to be removed from the new Meggitt Avionics factory before they could start the relocation.